QPW40cylinder and steel pipe external surface shot blasting machine is a specially designed machine for small diameter steel pipe or cylinder cleaning.

This machine has following features:

The speed of roller conveyor is adjustable. The pipe or cylinder will rotate and move forward when it is blasted to make sure the pipe or cylinder is thoroughly cleaned.

This machine uses big throw ability and high speed blast wheel, which highly improves cleaning speed and quality.

Inside of blasting cabinet, there is SPMn13 plate liner to protect the cabinet wall.

The plate liner is fastened by special material casting nuts, which is easy for replacement. It is the best protective material at present.

Abrasive controller is a pneumatic control valve, which is developed and produced by our company, easy and reliable.

2. Each part structure and performance

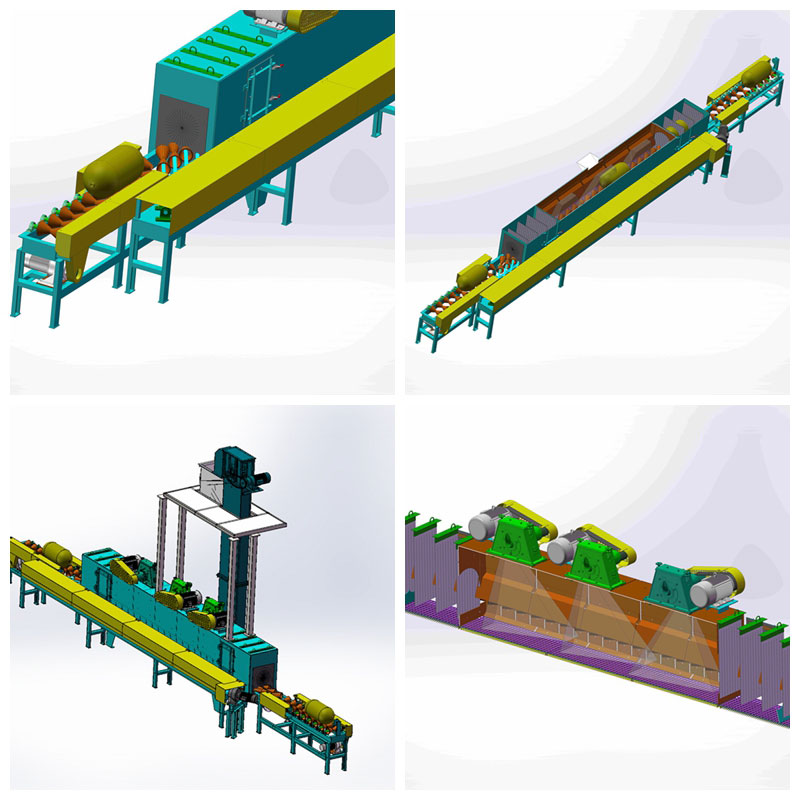

QPW40 shot blasting machine has following main parts: roller conveyor system, blasting cabinet, abrasive circulation and purify system, abrasive collection system, dust collector and electric control system.

2.1 V-Roller conveyor

● Roller conveyor system includes inlet rollers, cabinet rollers and outlet rollers. The rollers are driven by gear motor. There is a 30° angle between rollers and shaft direction with pipe moving direction. The rollers not only put the pipe move forward, but also make the pipe rotate when it moves forward. In this way, the pipe will be thoroughly blasted in all direction.

● All rollers must rotate synchronously. They are driven by frequency changing motors.

● The arrangement of rollers in blasting cabinet is simulated and confirmed by 3D software. The rollers totally avoid being blasted by abrasive directly.

● Each section of rollers has a control table, which can operate manually or automatically. So operator can control each section separately, which is convenient for maintenance and adjustment.

2.3.Blasting cabinet

Blasting theory

The arrangement of blast wheel is simulated by computer. There are 3 blast

wheels on upper of the cabinet to give through blasting of work pieces. Blast wheels

adopt transverse blasting theory. The blasting direction formed a 90 degree angle with

steel plate marching direction. Axial direction and work piece formed a proper angle

to get a perfect blasting effect.

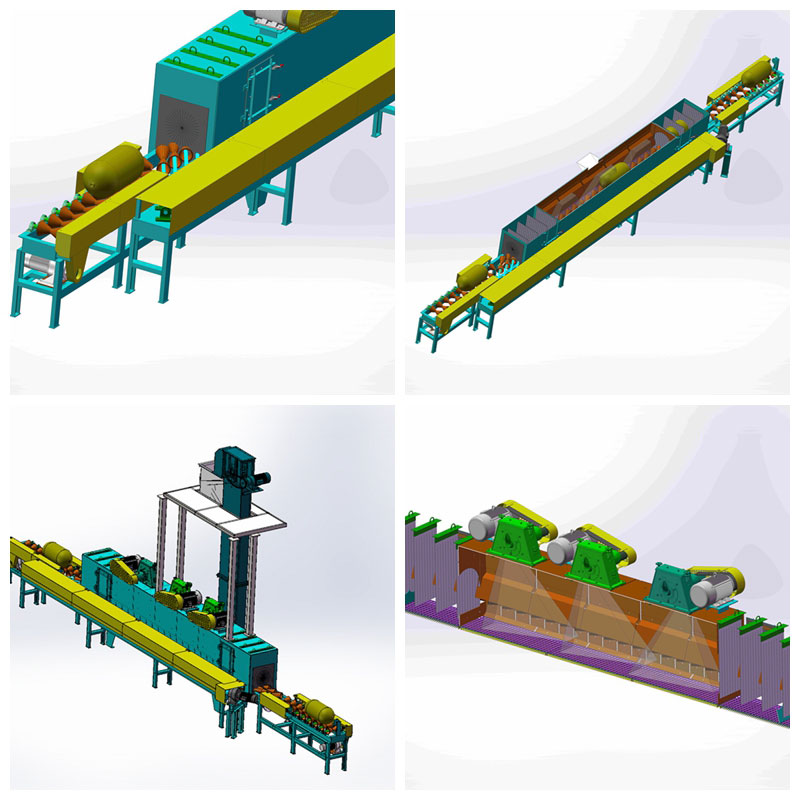

Features of blasting chamber:

Steel plate and beams welded structure, having enough intensity and rigidity. The shape and size of chamber, position and direction of blast wheels are confirmed by 3D simulation. Main blasting area has Manganese steel casting liner, 12mm thickness, good wear resistant performance. The fastening nuts to fix protective plate is made of high chrome. Chamber bottom has grating to protect bottom hopper and screw conveyor.

The wearable protective plates can protect chamber wall from abrasion. Treated SPMn13 liner plates have good reflect performance, which can reflect the abrasive to blast the workpiece again. Its surface hardness is over HB500. It is the best wearable material in this field.

Blast wheel mounting base and chamber wall use position pin and thorough bolts to fix, and between them there are good cushioning rubber mat to reduce vibration.

he protective plates installing way is cordwood way, and the nuts are casting cap nuts, whose life is longer than normal nuts.

The blasting cabinet uses SPMN13 steel protective liner with thickness 10mm.High manganese wear resist steel is the best choice for wear resisting purpose. It has the advantage that other material cannot compare with. Under big impaction force, high manganese steel plate surface will become hardener, the hardness increase from HB200 to HB500 to form a wear resistant layer on the surface. The outstanding features of high manganese steel plate is: first, the bigger impaction force comes, the higher wear resistant it will become; second, along with the hardening layer moves, new hardening layer will come out.

No.867 Century Avenue, Huangdao District, Qingdao, China

No.867 Century Avenue, Huangdao District, Qingdao, China 13361277779

13361277779 15908950799

15908950799 No.867 Century Avenue, Huangdao District, Qingdao, China

No.867 Century Avenue, Huangdao District, Qingdao, China 13361277779

13361277779 15908950799

15908950799