Belt Shot Blasting Machines are used for treatment small work pieces as following:Screws, steel bolts, in preparation for next galvanizing treatment,Aluminum die-castings and its alloys,Brass and steel hot pressing,Various mechanical components etc. and small casting parts , forge parts and soon on.

The rubber belt tumblast shot blasting machine is fitted with endless rubber conveyor belt gives gentle of turning of the parts to be shot blasted.The tumblast shot blasting is suitable for foundry, forging, surface preparation, aluminum deburring.

Applications:

Shot peening of heavily stressed components.

Desanding and descaling of castings and forgings.

Preparation of surfaces for protective coating.

Cleaning of castings and forgings.

Aesthetic finishing of dye castings of aluminum, zinc and alloy steels.

Removal of heat treated scales

1. Introduction

This machine can be used to derust and streng then the surface of workpieces with mass productions.The workpieces must accept collision. this series machines can be singlely used or together with others.

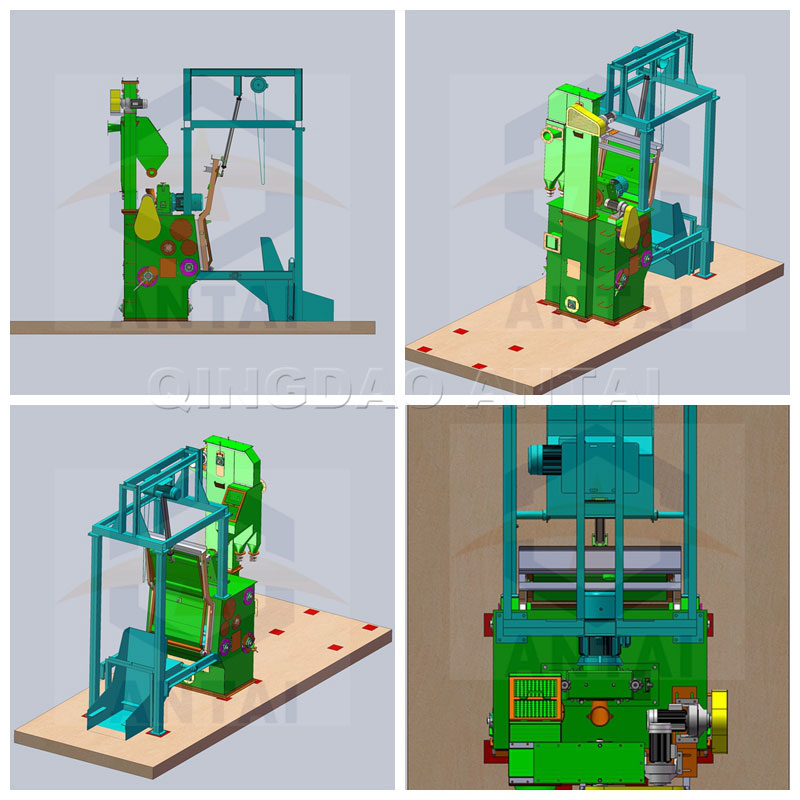

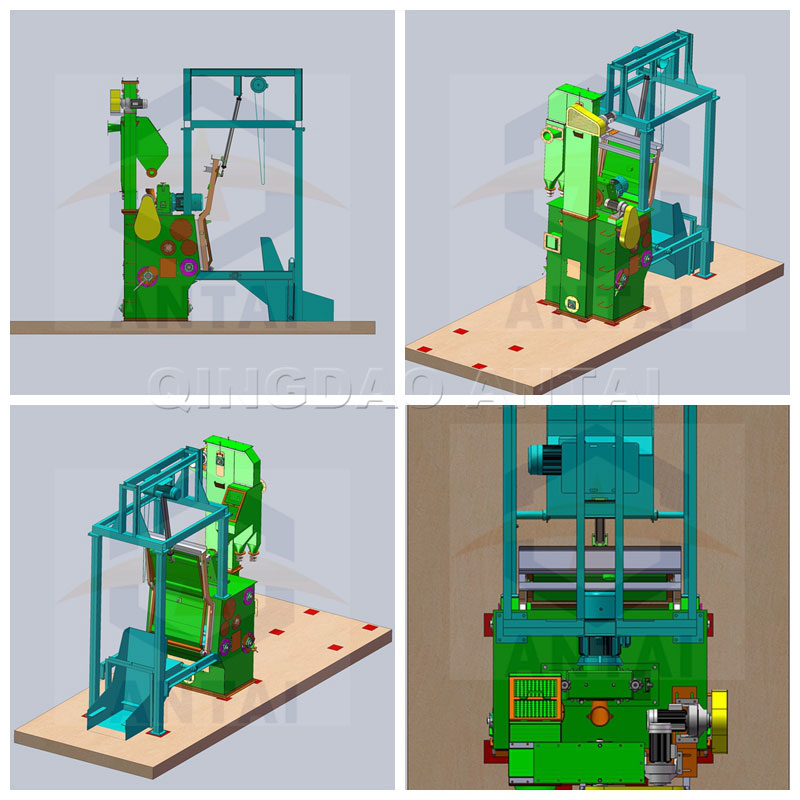

2. Features

A) No pit and save install fee.

B) Arrangenment of blast wheel is according with CAD.

C) The blast wheel adopts American Pangborn technology.

D) Novel design, compact structure and easy to maintain.

E) It adopt BE full shutter type separator.

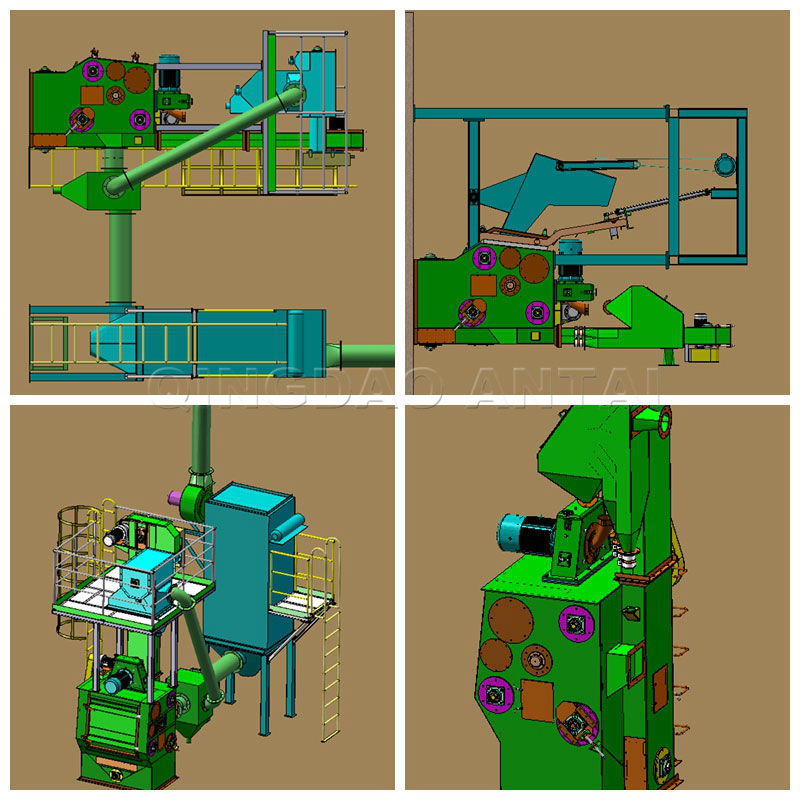

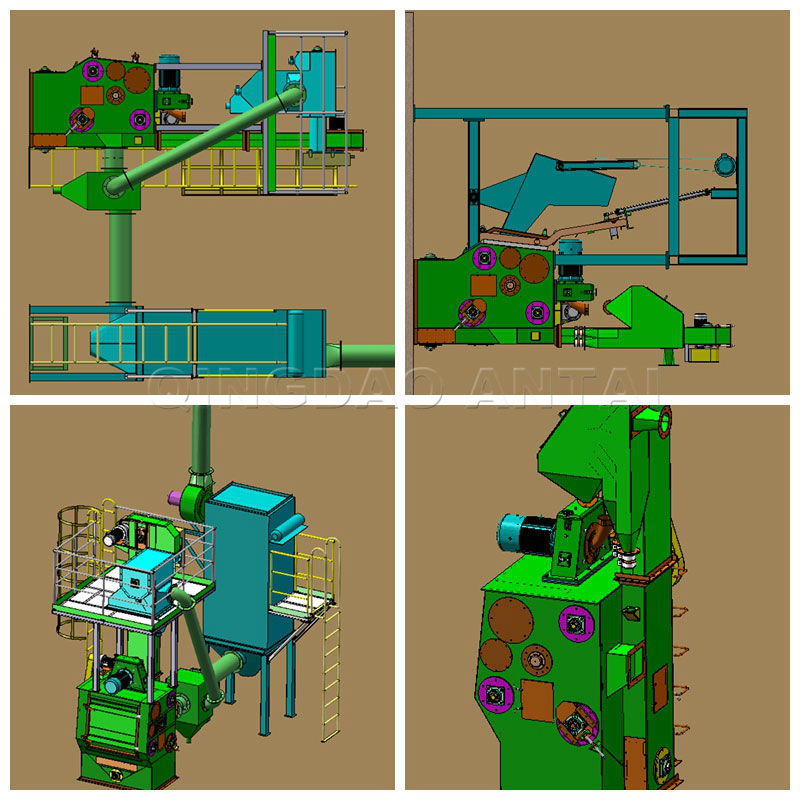

3. Composition

It consists of cabinet,rubber belt,flapdoor,blast wheel,feedingdevice,elevator,screw conveyer,magnetism system,dust collector system,electrical system.

If the machine is not suitable for your workpiece, please tell us the following information:

1) What kind of workpiece will you clean?

2) The size of workpieces(length, width and height of maximum workpiece,Length, width and height of minimum workpiece?)

3) How many the weight of maximum and minimum workpiece?

4) Please tell us your requirement cleaning efficiency?

According to your infomation, the most suitable machines will be designed for your workpieces.

|

Item

|

Units

|

Q326

|

QR3210

|

15GN

|

28GN

|

|

Productivity

|

t/h

|

0.6-1.2

|

1.5-2.5

|

5-6

|

10-12

|

|

Feeding amount

|

kg

|

200

|

600

|

1300

|

1500

|

|

Maximum weight of single piece

|

kg

|

10

|

30

|

230

|

363

|

|

Diameter of end disk

|

mm

|

Ø650

|

Ø1000

|

Ø1092

|

Ø1245

|

|

Effective volume

|

m3

|

0.15

|

0.3

|

0.43

|

0.79

|

|

Shot-blasting capacity

|

kg/min

|

100

|

250

|

480

|

700

|

|

Air volume for dedusting

|

m3/h

|

2200

|

5000

|

5300

|

6500

|

|

Power consumption

|

kw

|

12.6

|

24.3

|

49.3

|

64.5

|

|

Outline dimention

|

mm

|

3681*1650*5800

|

3972*2600*4768

|

4597*3262*5709

|

5300*5432*6814

|

No.867 Century Avenue, Huangdao District, Qingdao, China

No.867 Century Avenue, Huangdao District, Qingdao, China 13361277779

13361277779 15908950799

15908950799 No.867 Century Avenue, Huangdao District, Qingdao, China

No.867 Century Avenue, Huangdao District, Qingdao, China 13361277779

13361277779 15908950799

15908950799